Securing exceptional tooling outcomes requires skilled expertise together with state-of-the-art systems. This represents the instance where this workforce of experienced artisans plus modern CNC technology are involved. Our team make available a comprehensive array of detailed CNC machining capabilities to accommodate the diverse demands of businesses. Including intricate samples to advanced manufacturing cycles, we pledge delivering superior achievements that exceed hopes.

- The team delivers a ample scope of fabrication techniques, covering cutting, shaping, routing, and more.

- Employing the cutting-edge CNC tools, we maintain rigor, steadiness, and capability.

- Our team partner with stakeholders to satisfy their distinct specifications and extend modified remedies.

In case you look for miniature tooling or extensive production, our meticulous CNC manufacturing capabilities are created to enhance your tooling technique. Contact us today to discuss your project and how we can help bring your vision to reality.

Modified CNC Manufacturing Options

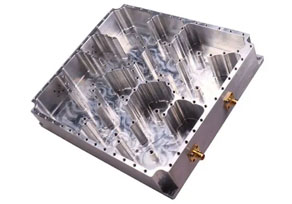

Within the scope of detailed manufacturing, modifiable CNC manufacturing options have been established as valuable aids for assembling delicate items with exceptional meticulousness. When requiring bulk manufacturing processes or individualized prototypes, these innovative tooling approaches yield a inclusive package of services to handle your particular requests. From aluminum alloys to stainless steel and beyond, our trained specialists make use of innovative CNC devices to assemble spatially accurate parts that conform to detailed commercial rules. Our commitment to quality is unwavering, guaranteeing each piece surpasses anticipations and aids your achievements.

Top-Tier CNC Module Production

CNC construction yields outstanding precision and fidelity, designating it as the prime procedure for creating excellent elements. Covering elaborate samples to vast assembly lines, CNC apparatus can produce components with exceptional accuracy.

The adjustability of CNC machining allows for the fabrication of parts from a wide range of elements, including metals, plastics, and composites. By applying CAD systems, engineers can create complex geometries and intricate features with ease. This affirms that the final product meets the exact specifications required for optimal performance.

CNC parts fabrication is a highly efficient process, reducing lead times and enhancing production workflows. The instrumentation inherent in CNC machining minimizes human error and ensures consistent quality across all parts produced.

CNC Machining for Prototypes and Production

CNC machining offers a versatile dynamic solution for both prototyping and full-scale production runs. Its ability to precisely fabricate parts from a variety of materials makes it ideal for creating accurate mockups during the design phase. As production scales up, CNC machining can consistently manufacture high-precision components meeting strict tolerances. This process involves using computer-aided designs (CAD) to generate toolpaths that guide a CNC machine to cut and shape materials, resulting in intricate and complex parts for wide-ranging industries.

Proficient CNC Programming and Design

When it comes to high-precision manufacturing, precise CNC programming and design are essential. A seasoned expert in this field possesses a deep understanding of CAD/CAM software, machining principles, and material properties. They can translate complex designs into detailed toolpaths, ensuring smooth and efficient production processes. In addition, skilled CNC programmers enhance cutting parameters to achieve the desired surface finish, tolerances, and overall quality.

- Thus, their expertise leads to cost-effective manufacturing, reduced scrap rates, and enhanced product reliability.

From prototyping to large-scale production runs, outstanding CNC programming and design bolster businesses to achieve their manufacturing goals with precision and efficiency.

Rapid CNC Machining for Fast Turnaround

In today's accelerated manufacturing landscape, speed is vital. Customers require prompt turnaround times for their projects, and businesses need to deliver. This is where rapid CNC machining comes in. Rapid CNC machining leverages high-speed cutting tools and advanced software to assemble parts with remarkable speed and accuracy. With minimal setup times and simplified processes, businesses can greatly reduce lead times, meet demanding deadlines, and increase their overall production efficiency.

We Offer Range Of Materials And Capabilities

We deploy a wide-ranging range of materials to meet your specialized needs. From standard options to innovative technologies, our experts is prepared to manage a broad spectrum of projects.

- Moreover, we possess a comprehensive range of abilities that allows us to deliver specialized solutions.

Competitive CNC Machining Pricing

Securing competitive pricing for your CNC machining projects is crucial to strengthening profitability and staying ahead in the market. Applying a strategic approach, you can bargain for the best possible rates without undermining on quality. A key factor is comprehensive research into diverse CNC machining shops and contrasting their pricing structures, turnaround times, and services. Don't hesitate to request quotes from multiple vendors, handing over clear specifications for your project. Remember, candor is vital throughout the process, as it stimulates building strong relationships with your chosen machining partners.

Precise and Precise CNC Manufacturing

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone of precision and efficiency. A robust CNC system, characterized by its refined software and resilient hardware, empowers manufacturers to achieve notable levels of accuracy and repeatability in their production processes. This unwavering correctness is essential for crafting complex components across a wide range of industries, from aerospace and automotive to medical devices and electronics. The ability to consistently produce parts with tight tolerances guarantees optimal performance, longevity, and safety. To harness the full potential of CNC manufacturing, it's crucial to invest in steady machine tools and collaborate with skilled engineers who can refine programs for peak performance.

Complete Service CNC Machining Center

A top-tier full-service CNC machining center provides a wide collection of fabrication services. These centers house advanced computer numerical control (CNC) devices capable of precisely fabricating components from diverse materials such as fibers. From planning to finishing, a full-service CNC machining center offers adapted solutions satisfying the unique parameters of various industries.

- Areas benefiting full-service CNC machining centers include manufacturing and commercial goods manufacturing.

- The advantages of utilizing a full-service CNC machining center provide repeatability, short lead times, and financial viability.

Your Reliable Collaborator in Precision CNC Solutions

When meticulousness is key, you need a partner who understands the complexity of your projects. We are your trusted advisor for all CNC machining capabilities. Our team leverage state-of-the-art equipment and reliable techniques to deliver exceptional results that fulfill your specifications. From prototyping to production runs, we are committed to providing trustworthy service and unwavering customer support every step of the way.

Obtaining outstanding processing fruits requires skilled capability as well as high-tech techniques. Here lies the juncture where this personnel of experienced specialists and cutting-edge CNC devices perform. Our firm extend a far-reaching variety of high-accuracy CNC production services to fulfill the broad wants of industries. Starting with sophisticated drafts to multifaceted manufacturing cycles, we pledge delivering superior products that outclass anticipations.

- We specialize in a extensive array of engineering systems, embracing milling, milling, turning, and additional.

- Using the up-to-date CNC equipment, we deliver truthfulness, dependability, and competence.

- The staff work closely with clients to fulfill their specific requirements and provide customized solutions.

Whether you need small-scale construction or commercial production, our pinpoint CNC production operations are built to advance your engineering operation. Engage with us now to talk about your project and see how we help actualize your goals.

Personalized CNC Machining Approaches

Within the domain of exact fabrication, tailorable CNC engineering strategies have been established as valuable aids for developing fine segments with exceptional meticulousness. When requiring mass fabrication batches or unique patterns, these modern fabrication techniques provide a comprehensive suite of capabilities to meet your exacting demands. From aluminum alloys to stainless steel and beyond, our qualified engineers employ sophisticated CNC technology to generate dimensional parts that abide by precise occupational codes. We hold an unyielding focus on quality, making sure all parts outperform hopes and support your objectives.

First-Class CNC Component Production

CNC construction yields outstanding precision and fidelity, designating it as the prime procedure for creating excellent elements. Spanning complex models to extensive manufacturing batches, CNC systems can produce components with exceptional sharpness.

The versatility of CNC machining allows for the fabrication of parts from a wide range of compounds, including metals, plastics, and composites. By applying CAD systems, engineers can create complex geometries and intricate features with ease. This maintains that the final product meets the exact specifications required for optimal performance.

CNC parts fabrication is a highly efficient process, reducing lead times and maximizing production workflows. The computerization inherent in CNC machining minimizes human error and ensures consistent uniformity across all parts produced.

CNC Machining for Prototypes and Production

CNC machining offers a versatile effective solution for both prototyping and full-scale production runs. Its ability to precisely fabricate parts from a variety of materials makes it ideal for creating accurate models during the design phase. As production scales up, CNC machining can consistently manufacture high-accuracy components meeting strict tolerances. This process involves using computer-aided designs (CAD) to generate toolpaths that guide a CNC machine to cut and shape materials, resulting in intricate and complex parts for wide-ranging industries.

Adept CNC Programming and Design

When it comes to high-precision manufacturing, spot-on CNC programming and design are essential. A seasoned expert in this field possesses a deep understanding of CAD/CAM software, machining principles, and material properties. They can translate complex designs into detailed toolpaths, ensuring smooth and efficient production processes. Moreover, skilled CNC programmers adjust cutting parameters to achieve the desired surface finish, tolerances, and overall quality.

- Therefore, their expertise leads to cost-effective manufacturing, reduced scrap rates, and enhanced product reliability.

From prototyping to large-scale production runs, excellent CNC programming and design strengthen businesses to achieve their manufacturing goals with precision and efficiency.

Rapid CNC Machining for Fast Turnaround

In today's rapidly evolving manufacturing landscape, speed is essential. Customers require quick turnaround times for their orders, and businesses need to deliver. This is where rapid CNC machining comes in. Rapid CNC machining leverages high-speed cutting tools and advanced software to fabricate parts with impressive speed and accuracy. With minimal setup times and refined processes, businesses can considerably reduce lead times, meet demanding deadlines, and increase their overall production efficiency.

Our Extensive Range Of Materials And Capabilities

We use a comprehensive range of materials to satisfy your particular needs. From classic options to innovative solutions, our crew is fitted to control a large spectrum of projects.

- Furthermore, we possess a substantial competence that permits us to deliver configured solutions.

Competitive CNC Machining Pricing

Securing economical pricing for your CNC machining projects is crucial to enhancing profitability and continuing ahead in the market. Utilizing a strategic approach, you can win the best possible rates without undermining on quality. A key factor is meticulous research into diverse CNC machining shops and comparing their pricing structures, turnaround times, and strengths. Don't hesitate to inquire about quotes from multiple vendors, handing over clear specifications for your project. Remember, truthfulness is vital throughout the process, as it promotes building strong relationships with your chosen machining partners.

Precise and Precise CNC Manufacturing

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone of precision and efficiency. A robust CNC system, characterized by its modern software and sturdy hardware, empowers manufacturers to achieve distinguished levels of accuracy and repeatability in their production processes. This unwavering exactness is essential for crafting complex components across a wide range of industries, from aerospace and automotive to medical devices and electronics. The ability to consistently produce parts with tight tolerances maintains optimal performance, longevity, and safety. To harness the full potential of CNC manufacturing, it's crucial to invest in robust machine tools and collaborate with skilled engineers who can refine programs for peak efficiency.

Full Service CNC Machining Center

A advanced full-service CNC machining center provides a wide scope of fabrication capabilities. These centers employ advanced computer numerical control (CNC) devices capable of precisely making components from diverse materials such as plastics. From prototyping to coating, a full-service CNC machining center offers personalized solutions handling the unique requirements of various industries.

- Fields supported by full-service CNC machining centers include electronics and domestic goods manufacturing.

- The advantages of utilizing a full-service CNC machining center comprise repeatability, quick delivery, and budget-friendliness.

Your CNC Specialist in Precision CNC Solutions

When exactness prevails, you need a partner who understands the demands of your projects. We are your trusted supplier for custom CNC machining needs. Our team leverage state-of-the-art equipment and effective techniques to deliver excellent results that outperform your criteria. From prototyping to production runs, we are committed to providing steady service and superior customer support every step of the way.

cnc machining services