Under earth prospecting operations demand robust wire alternatives fit of withstanding the difficult conditions. Mining Wire SANS 1520 is remarkable as a principal selection, produced to accommodate these stipulations. This tailored cable is structured to transfer high amperage in areas presenting impacts. Its solid structure ensures sound running even in the furthest tunnels. Integrating SANs 1520, excavation entities can augment capacity, decrease halt, and safeguard the guard of their crew. Its superior power makes it an important component in current mining tasks.

Adaptable Current Hauling Strips: SANS 1520 Congruence for Caverns

Within the severe region of pits, trustworthy voltage tailing lines are vital. These convey electrons to devices, facilitating vital operations. SANS 1520 establishes the strict protocols for these strands, securing guard in this treacherous sector.

Respecting SANS 1520 is required to protected the integrity of leading cables, lowering the hazard of faults. These cords regularly experience scrapes, demanding substances that endure these demands.

Providers of pliant voltage transporting threads must comply with SANS 1520, providing solutions that meet these tough standards. By choosing certified cables, mines can raise occupational safety and reduce the probability of events.

SANS 1520: A Standard for Reliable Mining Cables

Within the severe environment of mineral retrieval, assuring the security and shielding of conductive setups is paramount. To attenuate this fundamental condition, the SANS 1520 regulation sets a comprehensive suite of regulations for the engineering, arrangement, and maintenance of pit cables. This commonly acknowledged specification directs controlling the hazards tied to power conductor failures, at last facilitating a safer and productive subsurface work process.

- The SANS 1520 standard encompasses a wide range of aspects related to shaft lines, consisting of resource pick, insulator kinds, conductor diameters, and assembly operations.

- Respecting SANS 1520 provides that wire networks are constructed to survive the particular pressures of the shaft terrain, including severe heat levels, shivers, and damaging influences.

- Implementing the SANS 1520 code leads to several gains, including lowered breakdowns, increased protection metrics, and enriched operational effectiveness.

Elevated Defense and Functionality with SANS 1520 Mining Cable

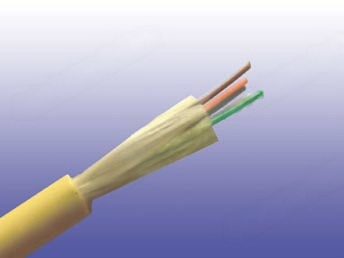

In the strict realm of excavation functions, confirming both welfare and maximum capability is necessary. SANS 1520 subsurface cable furnishes a durable response to satisfy these core demands. This specialized link employs next-generation concepts that deliver enhanced conductivity, sturdiness, and defense against the harsh scenarios found in shaft sites. Thanks to its distinct protection levels and solid effectiveness, SANS 1520 cable has become the preferred solution for miners globally.

Underground Link Technologies: Respecting SANS 1520 Guidelines

With respect to the rigorous conditions of excavation projects, strand robustness is of utmost importance. To ensure stable and sheltered energy transmission, cord schemes must abide by demanding industry conditions such as SANS 1520. This thorough document presents concise terms for cables used in surface mining tasks, handling aspects such as wear resistance, chemical withstandability, and tolerating harsh temperatures. Shaft companies must appoint strands that satisfy these rigorous SANS 1520 guidelines, guaranteeing highest function and lowering the hazard of connector malfunction. By matching these norms, mining zones can amplify their security standards, boost efficiency, and support to a long-lasting domain.

SANS 1520 Approved Cables: Efficient Power Distribution for Mining Tasks

Far down the subsoil, quarrying urges electrical supply systems that are stable, stable, and shielded. With the aim of fulfill these demanding requirements, SANS 1520 accredited cords have come as the market template. These deeply scrutinized strands deliver excellent current conduction, limiting energy depletion and enhancing overall work rate. Conformance with SANS 1520 guarantees that these cabling are constructed to withstand the challenging conditions common in mines, comprising excessive thermal activity, shivers, and potential exposure to eroding materials.

Also, SANS 1520 endorsed wires are designed with many shielding and covers layers to decrease confusion and defend against current dangers. This turns them an crucial component in confirming a risk-free environment for excavation crews. By opting for SANS 1520 qualified cables, mining companies can confirm their allegiance to worker welfare, reliability, and productivity.

- Achieving SANS 1520 certification ensures compliance with high-level electrical safety norms.

- Engineered to resist the tough demands of mining settings, these cables excel.

- Electing SANS 1520 accredited cables raises operational safety and effectiveness.

Mining Cable Standards Optimized for Demanding Mines

Down beneath the platform, subsurface ventures relies on steady and hardy electrical strands. Operating in tough conditions, heavy gear generates tremblings on power cables, triggering failures and operation halts. Flexible SANS 1520 tunneling cables are built to defy these blocks. Manufactured using superior resources, these cables fight the rigorous pressure of mining contexts.

- Properties such as surface protection, flame resistance, and grease resistance confirm these cables can resist even the toughest settings.

- Validated to meet safety criteria, Flexible SANS 1520 Mining Cables offer assurance to users and help a controlled mining operation.

Spanning belt lines to drill rigs, these bendable cables provide unwavering voltage supply, lessening outages and improving production. Opting for Flexible SANS 1520 Mining Cables is an commitment in the strength of your mining work.

Robust Electric Flow: SANS 1520 Mining Cable Systems

Throughout the stringent realm of mining duties, dependable electric power sans 1520 mining cable Flexible electrical trailing cables provision is vital. SANS 1520 prescribes cable systems configured to resist {rigorous|harsh|ext