Inside the realm of mechanical functions, defending the integrity and output of pipings is crucial. Collection of filth within lines can decisively impair transit speed, diminish production excellence, and augments maintenance outlays. To handle these challenges, pipeline cleaning techniques have sprung up as particularly powerful remedies for seamless line cleaning. A cleaning tool, usually a tube-shaped apparatus, is moved through the tube, successfully scrubbing dirt and delivering top functionality

Tube sanitation methods extend countless pros. They are flexible, ready to sanitizing pipelines of divergent dimensions and components. Furthermore, they are potent, executing the mission in a moderately rapid duration. By trimming downtime and optimizing pipeline performance, pipeline cleaning systems augment budget cuts and boosted operational work

Sterile Flow Strategies:

Keeping pipeline spotlessness is key for confirming yield protection and standards of supplied wares. Sanitary pigging systems grant a solid way to achieve this purpose. Pigs, dedicated implements, are deployed into pipelines to decontaminate by displacing residues and debris

- Various types of sanitary pigs come, each assembled for targeted cleaning needs.

- These pigs are fabricated from components that follow stringent decontaminated standards.

- Methodical sanitary pigging exercises boost avoiding product infection, lengthen pipeline lifespan, and increase total effectiveness.

Next-Generation Pigging Techniques for Enhanced Productivity

pigging systemThroughout the sector of channel maintenance, high-tech pigging technologies have turned into a major asset for maintaining peak functionality and safety. These cutting-edge systems mobilize breakthrough formulations and capabilities to effectively sterilize, analyze, and protect passages from corrosion. From automated pigs fitted with current analysis modules to engineered pigging instruments meant for fine tasks, evolution in this area is unceasingly expanding horizons. By leveraging these novelties, users can notably enhance pipeline strength, lessen downtime, and raise operational efficiency.

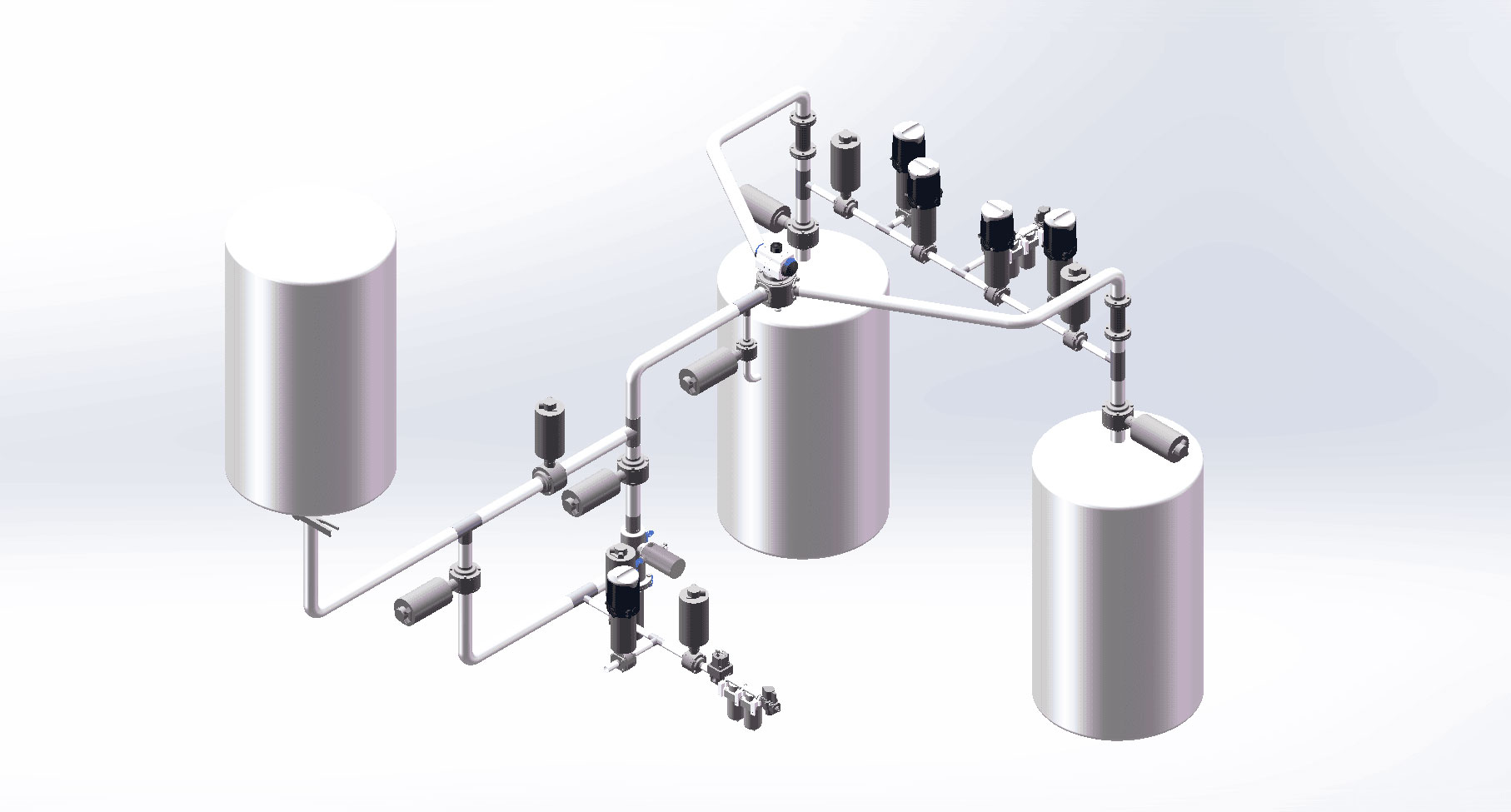

Broad Pigging System Layout and Assembly

Such broad-based pigging system entails a fundamental methodology for pipeline care. This system necessitates the introduction of dedicated implements called pigs, which travel through channels to disinfect, analyze, and preserve their stability. The blueprint puts weight on elements such as tubing girth, ingredient, pig form, and operational demands. A meticulously structured system secures potent pigging missions while curtailing downtime and potential injuries. Installation procedures demand careful organization, skilled professionals, and strict adherence to safety measures to ensure a secure and effective end

Industrial Pigging Systems for Multifaceted Operations

Engineering pigging equipment are essential tools used across a wide group of industries. These apparatus encourage secure and efficient disinfecting, review, and maintenance of pipes and other tube-like frameworks. Pigging involves sending purpose-built tools known as pigs through pipes to handle diverse missions. Common types of industrial pigging devices include cleaning pigs, inspection pigs, and delivery pigs. Cleaning pigs are constructed to eliminate debris, build-up, and fouling from pipelines. Inspection pigs are outfitted with detectors that acquire information about the status of pipe coatings. Transport pigs are deployed to distribute contents through pipelines. The use of industrial pigging products contributes numerous benefits, such as minimized downtime, enhanced pipeline durability, and maximized operational efficiency. These devices are widely operated in sectors such as oil and gas, water treatment, chemical production, and food manufacturing.A Detailed Guide to Pipeline Pigging

Pipeline pigging is an key approach used within the oil and gas industry to inspect pipelines. This necessary procedure embraces placing dedicated units, referred to as pigs, into the tube. Pigs are fashioned to traverse the length of the pipeline, conducting various roles.

Some classes of pigs are available, each customized for a specialized purpose. Common exercises of pipeline pigging cover surveying for defects, flushing, and pipeline rehabilitation.

- Benefits of Pipeline Pigging

- Repercussions on Operational Efficiency

- Categories of Pipeline Pigs

Trusted Sanitation using Pigging Systems

Pigging frameworks furnish a proven answer for promoting sanitation inside pipes. These technologies leverage engineered tools that progress through the tube system, skillfully cleaning accumulation. The operation is especially helpful for areas that demand rigorous cleanliness norms. Pigging mechanisms contribute a economical and quick approach for disinfecting passages, eliminating the threat of pollution.

Choosing Pigging Devices for Particular Conditions

Pigging apparatus acts a indispensable role in effective pipeline performance. When appointing pigging hardware, it is essential to consider the individual prerequisites of your application. This entails evaluating features such as pipeline thickness, flow current, product type, and repair needs.

Diverse pigging choices are available, each developed for distinct uses. In particular, some pigs are crafted for evaluation, while others are deployed for eradicating fouling or separating product lots.

In addition, pigging tools items should be harmonious with the handled element.

It is generally best to seek advice from a specialist in pigging practices to validate that you pick the most fitting device for your specific specifications.

Integrated Pipeline Solutions - A Practical Approach

Tubular maintenance systems present a expansive variety of benefits for branches built upon ducts. By efficiently disinfecting and inspecting duct internals, pigging systems promote operational effectiveness and diminish maintenance expenditures.

A fundamental merit of pigging systems is their aptitude to clear contaminants such as mineral deposits, debris, and oxidation products. This systematic washing promotes frictionless pipeline stream and prevents costly downtime.

Also, pigging systems can be employed to survey the quality of pipelines, identifying imminent complications before they worsen into grave issues. This preventative plan boosts to extend the lifespan of pipelines and minimize overall maintenance costs.

Preserving Hygiene in Pigging Workflows

Swine husbandry methods essentially emphasize appropriate hygiene protocols to minimize the propagation of pathogens. Observing rigorous hygiene practices supports a sound surroundings for pigs, so that produces heightened health outcomes and yield.

Systematic cleaning and disinfection of enclosures is crucial to minimize the level of harmful germs. Effective waste management also fulfills a fundamental part in supporting hygiene.

Also, {workers