Initiating

Launched segregation technology has materialized as a state-of-the-art method for amplifying refuse categorization effectiveness. This approach employs the principle of momentum principle to sort garbage components based on their compactness. By flinging scrap into a housing, ballistic separation can precisely discriminate various types of discard, covering plastics, metals, and biological materials. This efficient strategy to junk management can considerably augment recycling rates and reduce landfill size.

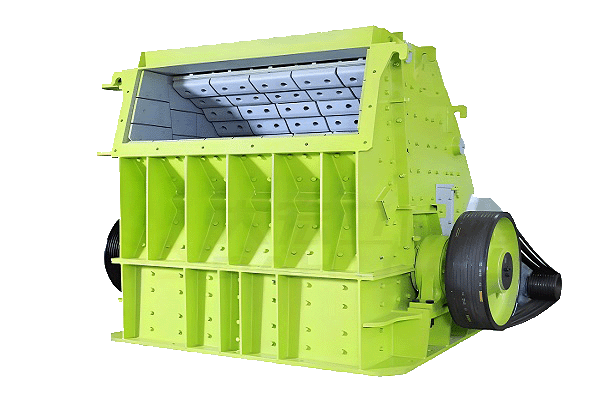

waste sorting machineRevolutionary Substance Recuperation: The Impact of Kinetic Separators

Momentum separators are reshaping the industry of substance recuperation. These next-generation devices utilize high-velocity air streams to classify elements with significant accuracy. Unlike ordinary ways, ballistic separators efficiently handle a diverse range of objects, from plastics and metals to glass and organic waste. This diversification makes them ideal for both massive recycling centers and limited operations.

The fundamental pace of ballistic separators grants a significantly higher recovery rate compared to conventional techniques. Furthermore, their space-saving design enables for integration into existing recycling structures with restricted disruption. As the demand for sustainable procedures aims to develop, ballistic separators are likely to play an significantly instrumental role in constructing a circular economy.

- Upsides of Ballistic Separators:

- Advanced recovery rates

- Systematic material separation

- Variety for diverse materials

- Scaled down operational costs

- Earth-oriented impact reduction

Elevating Metal Extraction: High-Performance Metal Shredders in Action

The ore extraction area is steadily seeking fresh ways to raise efficiency and reduce earth-related impact. High-performance metal shredders have materialized as a important resolution, presenting unparalleled capabilities for processing abundant volumes of materials. These modern machines leverage leading technology to fragment recyclables, classifying valuable metals from residuals with outstanding accuracy.

- Furthermore, high-performance metal shredders are known for their durability and lasting quality, ensuring consistent performance even under demanding requirements.

- Thus, these machines contribute to the green management of metal extraction by minimizing waste and maximizing resource utilization.

The incorporation of high-performance metal shredders is advancing the industry, spurring advancements in metal recycling and facilitating a more sustainable future.

Advanced Ballistic Separation for Diverse Recycling

Breakthroughs in recycling method are crucial to curtail the planetary damage of waste. A novel technique gaining traction is the ballistic separator. This instrument employs centrifugal force to competently sort recyclable components based on their size. By arranging materials into clear streams, the ballistic separator simplifies the recycling system, leading to increased recovery rates and a expanded range of recyclable materials. This milestone holds immense opportunity for improving recycling systems and facilitating a earth-conscious future.

AI-Powered Waste Sorting: Uniting AI and Ballistic Sorters

The future of waste management is developing swiftly, driven by the urgent need to limit environmental impact. Leading technologies are being employed to advance recycling techniques and generate a more sustainable future. One such development is machine-learning waste sorting, which employs the power of ballistic separators and artificial intelligence (AI) to categorize waste ingredients with unprecedented efficiency.

Ballistic separators run by using high-speed air currents to send different sorts of waste based on their size, shape, and density. This primary stage of separation curtails the complexity of the sorting technique for AI algorithms.

Cutting-edge AI models can then evaluate images and data from sensors to discern specific materials with exceptional accuracy. This blend of ballistic separation and AI enables a greatly efficient and streamlined waste sorting system.

Enhancing Waste Management: A Comprehensive Guide to Waste Sorting Machines

Waste sorting is a key step in effective waste management. Manual sorting can be lengthy and unsatisfactory, leading to contamination and boosted costs. To address these challenges, advanced waste sorting machines have emerged as a strong solution. These machines exploit modern technology to quickly sort various waste materials into designated categories.

There are numerous types of waste sorting machines available, each designed for unique applications. Some common types include sensor-driven sorters, which rely on optical signals to distinguish different materials. Besides, robotic arms and conveyor belts can be fitted to control waste with faithfulness. By automating the sorting process, these machines substantially improve efficiency and reduce manual labor requirements.

- Pros of using waste sorting machines include:

- Upgraded efficiency in sorting waste materials

- Diminished labor costs and personnel effort

- Raised accuracy in separating recyclable materials from non-recyclable waste

- Mitigation of contamination in recycling streams, leading to amplified quality recycled products

- Environmental benefits through greater recycling rates and reduced landfill waste

Progress in Recycling

Classic recycling processes have long been the usual procedure for arranging and processing recyclable objects. These methods often rely on manual arrangement by humans, which can be lengthy and prone to flaws. However, recent advancements in technology have led to the emergence of cutting-edge recycling systems, such as ballistic separation.

Ballistic separation leverages the strength of impact to divide different materials based on their size, weight, and shape. This high-speed method can rapidly handle large volumes of mixed recyclables, reducing manual labor and improving the accuracy of sorting.

Compared to traditional methods, ballistic separation offers several benefits. It is a much more automated process, requiring less human intervention and minimizing the risk of contamination. Additionally, it can handle a wider variety of materials, embracing plastics, metals, glass, and paper. This increased efficiency and flexibility make ballistic separation a advantageous solution for modern recycling operations.

Exploring A Ballistic Separator for Municipal Solid Waste

This assessment scrutinizes the implementation of a ballistic separator in a city solid waste management facility. The primary objective of this project was to elevate the competence of waste dividing. The study reviews the functional aspects of the separator, including its architecture, loading process, and segregation method.

Furthermore, the analysis assesses the importance of the ballistic separator on waste quality.

- Information collected from the machine functioning reveal the benefits of the implemented solution.

- Issues faced during the deployment process are also highlighted.

Advice for future enhancements based on the study's findings are presented.

Elevating Material Recovery Through Shredding and Separation Processes

In the field of waste management, proficiently recovering valuable materials is critical. Shredding and separation techniques play a important role in achieving this goal. By forcibly reducing materials to smaller fragments, shredding simplifies the subsequent separation stages. Advanced separation technologies, such as magnets, screens, and air classifiers, can then separate assorted material types with high exactness. This compound approach creates a higher rate of material recovery, minimizing landfill waste and boosting a circular economy.

Choosing a Waste Sorting Machine: Key Considerations

Waste sorting technology are vital for productively managing waste and promoting reuse. When opting for a waste sorting machine, it is vital to consider several variables to ensure it meets your unique needs.

First, determine the type of waste you will be organizing. Different machines are specialized for assorted types of waste, such as plastics, paper, metals, and organic materials. Next, weigh the volume of waste you generate. This will influence the scale of the machine you require. A increased machine is necessary for high-volume waste streams.

Also, include the space available at your plant. Waste sorting machines come in various sizes, so ensure there is sufficient room to fit the machine and allow for uninterrupted operation. Another important factor is the magnitude of automation you require. Manual machines offer varying degrees of labor engagement.

Finally, study the operational costs associated with different machines. Some machines may call for more frequent adjustments than others.

Increasing Landfill Diversion Rates with Advanced Separation Technologies

Landfills are a serious source of environmental impairment. To reduce this challenge, many communities are zealously seeking ways to increase landfill diversion rates. Advanced separation technologies offer a powerful solution by expertly sorting recyclable materials from waste streams. These innovative technologies leverage monitors and next-gen algorithms to identify various components. This brings to a increased recovery rate of recyclable items, due to this reducing the amount of waste sent to landfills.

The integration of these advanced separation technologies can bring countless gains. At first, it defends natural resources by recycling valuable materials. Additionally, it curtails greenhouse gas emissions associated with waste disposal and the generation of new materials from raw resources.

Closing