Beginning each inspection pertaining to exact external finishing techniques aimed at fabrication domains

Accomplishing steady achievements inside its manufacturing tasks? Fineness smoothing processes constitute essential to attain reaching first-rate unit condition as well as augmented output. Our team equip such broad selection comprising modern approaches, including chemical passivation, grinding, coupled with machining, aimed at cope with even the most challenging applications. The capable qualified team cooperates with customers to formulate special processing programs intended to optimize material features and secure dimensional cohesion. At last, these thorough methods contribute to reduced expenditure and enhanced efficiency for your corporation.

Critical Braze Sanitation Approaches & Apparatus

Appropriate seam treatment is entirely crucial for guaranteeing the stability of any formed connection. That way removes remnants, voids, and other pollutants that can degrade resilience. Various approaches exist, including non-automated rubbing with tool tools, and power sanding. Tailored devices, such as transportable mechanical grinders, pin removers, and corrosion treatments, are frequently engaged for more potent results, particularly on broad welds. Furthermore, alkali compounds can be utilized to further wipe out stubborn deposits. Identifying the appropriate technique and associated devices depends on the fabrication metal, dimension, and necessary quality.

Pertinent Issues:

- Assembly Analysis

- Construction Study

- Construction Defense

Shaping Finishing: Systems & Equipment

Realizing a smooth, functional covering on manufactured parts is crucial, and burr extraction plays a vital purpose in that process. Conventionally, this was a manual, hands-on task, but modern foundry operations increasingly leverage advanced cleaning tools. These processes range from simple instrumental brushing and grinding to sophisticated automated systems employing machine deburring cells and even abrasive spraying techniques. Ultrasonic detergent-free cleaning offers a careful solution for delicate items, while flame deburring is frequently used for high-grade materials. The selection of the appropriate refinement method depends significantly on the matter, part configuration, and desired smoothness. Additionally, understanding the trigger of burr formation—often related to casting frame design or production parameters—can help minimize them altogether.

Conductive Strip Brush Applications

Charged deburring strip implements find extensive utility across a array of industries, largely due to their gentle yet effective action. Specifically, they excel in removing hard burrs from stamped metal pieces, preparing materials for subsequent application processes like powder spraying. Beyond deburring, these brushes are frequently used for precise surface adjustment prior to welding, offering a superior alternative to abrasive processes that can introduce surface imperfections. Furthermore, their ability to entirely remove scale and oxides makes them valuable in repair operations on bulky equipment.

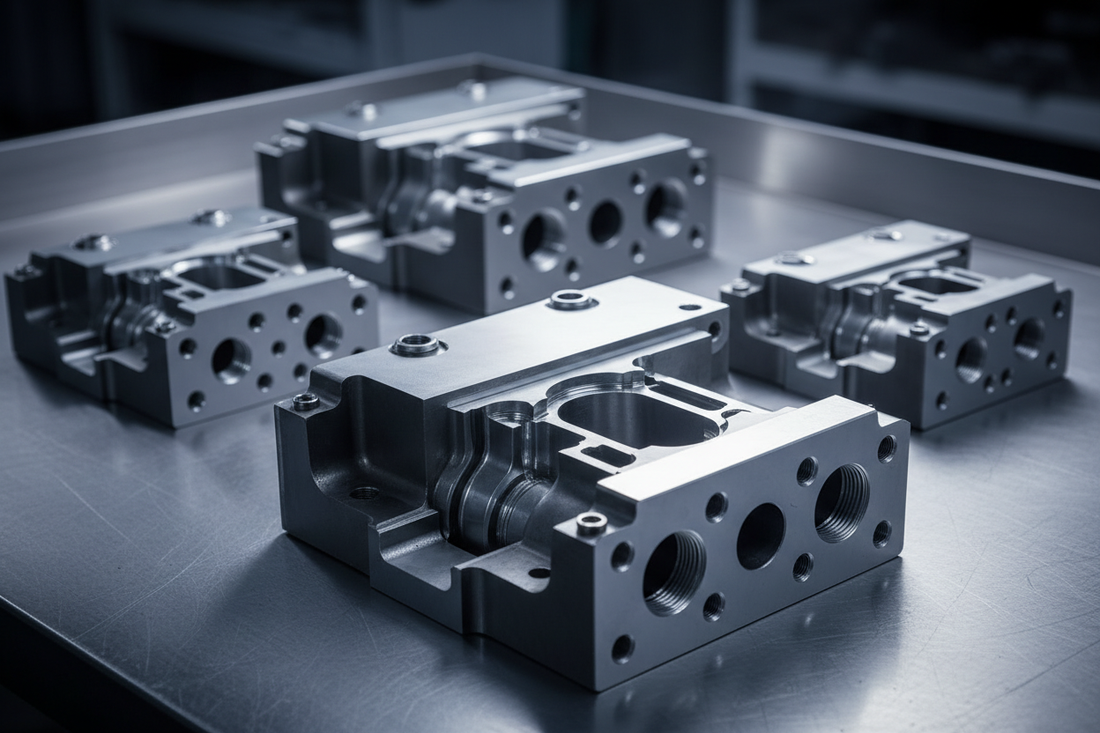

Exterior Refinement for Crucial Components

Securing optimal performance and amplified longevity for essential machine segments frequently necessitates dedicated surface refinement approaches. This isn't merely about aesthetics; it’s about altering the infinitesimal structure of the component to reduce attrition enhance oxidation resistance, and improve complete functionality. Numerous approaches, including polishing, lining, and laser texturing, can be conscientiously applied depending on the specific application and the intended outcome. The selection of a predetermined refinement method must always consider the fabric's properties and the performing environment to avoid unintended consequences and increase the component's consistency.

Automated Bond Cleaning Platforms

The impetus for consistently high-quality welds in modern production environments has spurred significant advancements in link post-processing techniques. Automated removal mechanisms are rapidly gaining popularity as a solution to traditional, labor-intensive methods like abrasive blasting or manual grinding. These advanced equipment often incorporate technologies such as laser sanitation, high-pressure waterjet abrasion, or specialized abrasive application, ensuring efficient and precise deposits eradication without damaging the underlying joint. Implementing these mechanized solutions leads to reduced resource costs, improved safety, and a more consistent quality that directly impacts the engineering soundness of the final product. The ability to integrate these equipment into existing processing lines further enhances their appeal across a wide range of industries, including construction and construction.

Smoothing Molds for Peak Functionality

For the purpose of reach peak consequences from your materials, devising is a vital stage. Offsets, a widespread byproduct of the forming procedure, can reduce capability, result in risk problems, and detrimentally weaken surface condition. Therefore, exhaustive burr removal – which may involve operated practices or programmed platforms – is critical for giving a first-class polished manufacture suitable for its destined task. This action exclusively improves work but also suppresses the potential for malfunction.

Clear-cut Detoxification with Line Scrubbing Methods

Achieving exceptional clarity in rigorous engineering applications often requires expert solutions. Blade sweeping systems offer a potent approach to remove residue from intricate areas. These new systems utilize skillfully crafted scrubbers to provide consistent interaction – crucial for precision disinfection and safeguarding product quality. Explore the benefits of band buffing practices for your next sterilization project.

Electrochemical Cleaning for Welds & Surfaces

Conductive cleaning offers a effective method for conditioning welds and various element classes. This process, fundamentally engaging electrochemistry, extracts oxides, scale, residual welding fumes, and other foreign bodies that can weaken subsequent processes like painting, review, or further fabrication. Unlike abrasive strategies, electrolytic refining provides a mild action, minimizing harm to the base material and leaving a remarkably sterile surface. It's especially constructive for complex patterns and inaccessible areas where manual abrading would be unfeasible. A carefully monitored electrolyte liquid and electrical power are indispensable for achieving equal results.

Sophisticated Fabrication Deburring Processes

After traditional physical deburring, modern casting facilities are increasingly employing innovative processes to achieve superior edge finishing. These innovative deburring procedures often involve a combination of automated systems and precisely controlled variables. Laser deburring, for instance, offers exceptional accuracy and allows for detailed geometries to be flawlessly cleaned, minimizing surface removal and maximizing element integrity. Furthermore, machine-driven deburring cells, utilizing rotating tools, are becoming rampant, providing increased throughput and reliable results, particularly for substantial production runs. The selection of the appropriate finishing method depends heavily on the molding alloy, artifact geometry, and desired surface characteristics.

Cutting-edge Exact Smoothing and Linear Polishing Innovation

The unabated pursuit of surface superiority in modern manufacturing demands ever more advanced solutions. Among these, precision enhancement utilizing line scrubbing mechanism stands out as a powerful solution. This approach, frequently employed across diverse industries like aerospace, offers distinct advantages in achieving stable material loss, perfecting, and cleaning results. Unlike traditional systems, strip conditioning technology allows for highly controlled material removal and the ability to access fine geometries with a level of accuracy previously unattainable. Furthermore, advancements in strand adoption and mechanism architecture continue to expand the applications of this vital polishing strategy.

abrasive brush

abrasive brush